How to test your adhesive?

I am just beginning to build my first woodworking project using glue. I've heard that there are several tests to help determine if your glue is holding properly. What are those tests? I am just beginning to build my first woodworking project using glue. I've heard that there are several tests to help determine if your glue is holding properly. What are those tests?

Good question! There are actually four stress tests you will want to perform: tensile, shear, cleavage, and peel. Use the same materials and adhesives that you plan to use on your project, and allow the adhesive to cure according to the manufacturer's instructions. Good question! There are actually four stress tests you will want to perform: tensile, shear, cleavage, and peel. Use the same materials and adhesives that you plan to use on your project, and allow the adhesive to cure according to the manufacturer's instructions.

If you use the correct adhesive, apply it properly, and allow it to cure according to the manufacturer's recommendations, failures will occur in the wood, not the glue joint. A good glue joint will actually be stronger than the wood surrounding the glue line. These tests should help you verify that you have selected the correct adhesive for your application.

|

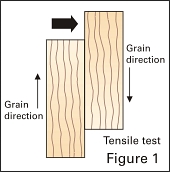

Tensile Test: Glue two blocks together face to face with their ends offset (figure 1). After curing, secure the tester in a wood vise with the glue joint free. Using a hammer, smack the upper block away from you. If it breaks on the glue line, you have a bad glue joint. You have a good bond if the sample breaks somewhere other than along the joint or if it pulls away portions of the wood surface. |

|

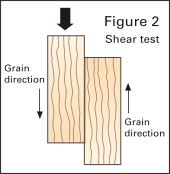

Shear Test: Glue up a similar pair of blocks as you prepared for the tensile test. Secure the sample in a vise, but leave space between the higher block and the vise (figure 2). Smack down on the end grain of the upper block. If the blocks are properly bonded, you'll have difficulty breaking them apart. If the wood breaks, rather than the joint, you have a good bond. |

|

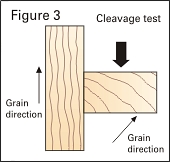

Cleavage Test: Glue the edge of one block to the face of another to form a T-shaped sample (when viewed from the end grain). Place the top of the T in the vise so the tail rises above it (figure 3). Smack down on the tail of the T. What broke loose—the wood surface or the glue line? The parts will likely break apart easily with this edge-to-face grain glue-up. Dowels or biscuits can add mechanical strength to such a joint. |

|

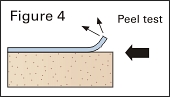

Peel Test: This test evaluates the bond of veneers and plastic laminates. After the glue has cured, try lifting a corner (figure 4). If you have a good bond, the material will break and/or split when you try lifting it. |

As I mentioned before, if you use the correct adhesive, apply it properly, and allow it to cure according to the manufacturer's recommendations, failures will occur in the wood, not the glue joint. A good glue joint will actually be stronger than the wood surrounding the glue line.

Copyright © 1996 & 2008 LAF/C.R.S., Inc. All rights reserved. The previous article,

in whole or in part, appeared in the September/October 1996 issue of

Woodworker's Journal.

[ Back to Top ]

|