Review Summary

O'Berry Enterprises

3154

Counter Snap for Decks

Suggested Retail $12.95

Reviewed by Leon A. Frechette

1998 Updated 02/22/07

O'Berry Enterprises - Counter snap headless deck screw

The Counter-Snap headless deck screw, developed by O'Berry Enterprises, Inc., is a 3-inch screw with an "interesting twist." For individuals who prefer to fasten decking boards from the topside, this product brings a finishing touch to deck construction.

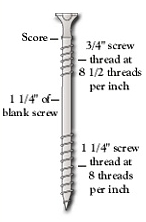

This specially designed screw is scored at the top, followed by 3/4" of thread, then 1 1/4" of blank shaft, and finally 1 1/4" of threads that run to the tip of the screw. This is referred to as a "doubled-pitched" screw, a design that allows the top threads to pull the decking materials closer to the framing member (joist). The score mark is engineered to snap 1/4" below the surface of the decking material.

These headless screws produce a better-looking finish surface than a screw with a head. In softwoods it is not necessary to drill a 1/8" pilot hole except at the ends (to help prevent the ends from spitting); however, in hardwood, a pilot hole is required for fastener installation. While the product can be used with 1 1/2" decking material, the product was truly designed for 5/4 material because only 3/4" of the threads actually secure the decking board.

To use the Counter Snap Headless Deck screw, first place the Counter Snap die cast fixture on the deck surface and slide a screw into the hole. Install the screw using the #2 recessed square driver bit that's been provided with the kit, making certain you apply pressure on the deck board itself when installing the special deck screw. After driving the specially scored screw into place, rock the fixture back and forth until the screw shank snaps off at the score, leaving the threaded portion of the screw 1/4" below the surface and a surface hole only 1/8" in diameter. To use the Counter Snap Headless Deck screw, first place the Counter Snap die cast fixture on the deck surface and slide a screw into the hole. Install the screw using the #2 recessed square driver bit that's been provided with the kit, making certain you apply pressure on the deck board itself when installing the special deck screw. After driving the specially scored screw into place, rock the fixture back and forth until the screw shank snaps off at the score, leaving the threaded portion of the screw 1/4" below the surface and a surface hole only 1/8" in diameter.

The Counter Snap Headless Deck screw is almost like a finish nail with threads. When the head is completely seated into the countersunk hole, it will snap off under pressure. The remaining hole can be filled, but the hole itself will begin to shrink within 30 minutes, provided it is in a softwood and was not pre-drilled. I tried a little hot water on the hole and within a few minutes it had just about disappeared. The Counter Snap Headless Deck screw is almost like a finish nail with threads. When the head is completely seated into the countersunk hole, it will snap off under pressure. The remaining hole can be filled, but the hole itself will begin to shrink within 30 minutes, provided it is in a softwood and was not pre-drilled. I tried a little hot water on the hole and within a few minutes it had just about disappeared.

One area of concern involved the fixture. When working with softwoods or softwoods with a slight crown, I noticed the bottom of the fixture left an impression about 1" in diameter. It is not as noticeable in perfectly flat wood, and with time the wood will return to its original state.

You can correct the situation

by drilling a 5/16" hole in the center of a 3/32" steel

plate that's at least 4 1/2" x 4 1/2" in size.

Then countersink the existing hole in the fixture 3/32" deep

(the thickness of the steel). Now you can place the fixture on the

steel base and you are ready to fasten deck boards. You will lose

some labor time because the plate and the fixture do not attach

as one unit. However, the large plate absorbs and evenly distributes

the pressure—thus leaving no marks.

The Counter-Snap headless deck screws are better suited for composite or alternative decking material. However these materials have different densities, so a pilot hole may be required. I suggest that you test a small sample first to see if the screw passes through without snapping. If it does, then a pilot hole is in order. On many composite boards, if you don't have to pre-drill, the screw will leave a small bump (a mushroom effect) that can be hammered down to conceal the screw.

Another reason for using Counter-Snap with composite over treated materials is because the preservatives used in treated materials contain lots of copper. Once the screw snaps off, there is a greater chance of galvanic reaction between dissimilar metals and the copper used in the preservative. This reaction can be avoided if composite decking material is used rather than treated decking material.

It really comes down to personal preference. I'm not a huge fan of installing fasteners through the face of decking material (I prefer to install a decking system from the underside), but I believe Counter Snap Headless Deck screws are a better alternative than using nails or screws with heads. My professional concern is that any fastener installed from the top surface (through the decking surface) will act as a wick and invite water into the interior of the framing members, a good way to damage them.

Copyright © 1998 & 02/22/07 LAF/C.R.S.,

Inc. All rights reserved. The previous

article, in whole or

in part, appeared in the February 1998 issue of Tech Directions.

Looking for home improvement Q&As? Click here!

[ Back to Top ]

|